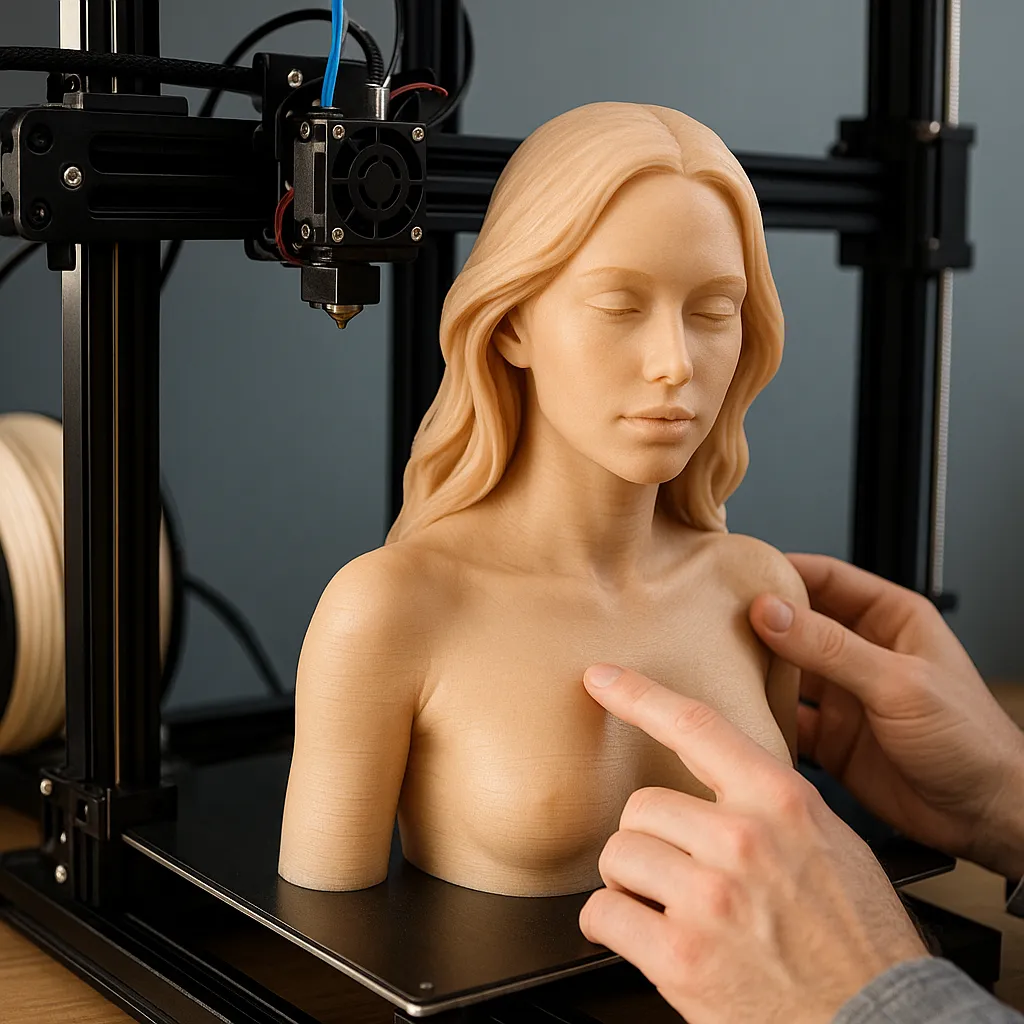

3D printing, also known as additive manufacturing, is reshaping industries across the globe by making production faster, more flexible, and more personalized. One area that is experiencing a dramatic transformation is the creation of lifelike products — including companion dolls, humanoid figures, and realistic mannequins. While these items are often misunderstood or connected only to adult industries, in reality, 3D printing is enabling new opportunities in healthcare, education, and design.

From Mass Production to Personalization

Traditionally, lifelike products were created using molds, requiring large-scale manufacturing that made customization expensive and limited. With 3D printing, each piece can be designed digitally and produced layer by layer. This makes it possible to tailor details such as size, shape, texture, and even skin tones for individual needs. The shift from standardized products to personalized companions allows users to receive items that feel unique and authentic.

Material Innovation in 3D Printing

Another key change is the development of new printing materials. Beyond plastics, manufacturers now use silicone, resins, and even hybrid materials that mimic the look and feel of human skin. These innovations improve durability and comfort, while also opening doors for more advanced design features. Some companies are experimenting with bio-compatible materials that could eventually be used in medical therapy, prosthetics, or rehabilitation tools.

Applications Beyond Adult Use

The biggest misconception about lifelike products is that they exist only for one type of consumer. In reality, the customization made possible by 3D printing has far-reaching benefits:

- Healthcare Training – Medical schools use lifelike mannequins to simulate surgeries or patient interactions, helping students practice in a realistic yet safe environment.

- Therapy and Rehabilitation – Custom models can assist in physical therapy, helping patients regain motor function with tailored devices.

- Education and Child Development – Realistic dolls and models are being used in classrooms to teach empathy, caregiving, and social interaction.

- Entertainment and Art – Artists and filmmakers use customized figures to bring characters to life in creative projects.

These examples highlight how 3D printing is expanding the role of lifelike products far beyond their original perception.

Cost Efficiency and Accessibility

One of the major advantages of 3D printing is affordability. In the past, creating a custom product required specialized molds and long production times, often making personalization available only to a small group of consumers. Now, digital files can be quickly modified, and printing can be done on demand. This reduces waste, lowers production costs, and makes personalized lifelike products more accessible to the wider public.

The Future of Customization with 3D Printing

As technology evolves, the future promises even more realistic and interactive designs. With the integration of sensors, robotics, and artificial intelligence, 3D-printed lifelike companions could become fully interactive, offering support in everyday life. Additionally, sustainable printing materials may reduce the environmental footprint of production, aligning with the global push toward eco-friendly solutions.

Final Thoughts

3D printing is revolutionizing the way lifelike products are made by shifting the focus from mass production to personalization. Beyond aesthetics, this innovation supports industries such as healthcare, education, and therapy, where realistic models provide real value. As materials and techniques continue to improve, the line between technology and human experience will blur even further, making these creations more meaningful and widely accepted in society.